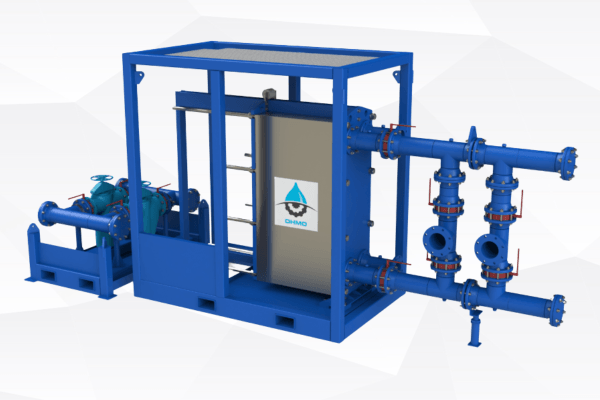

How the WTDS Disc Press works

After passing through the flow control and flocculation tanks, the sludge enters the non clog thickening zone. This consists of a drum which houses a screw running at a fixed speed. The drum consists of spacers, fixed and moving rings. The moving rings have a smaller outer diameter than the screw. As the screw operates, the moving rings continuously clean the sludge from the gaps allowing filtrate to pass and ensure clog free operation.

As the sludge progresses along the screw, the pitch narrows, increasing the pressure and dewatering efficiency.

Sludge can be taken directly from source e.g. aeration tank, which means costly upstream storage tanks are not necessary. As the thickened/dewatered sludge is low volume the cost of downstream storage tanks is also massively reduced.

Existing installations direct dewater from 3-4% DS to over 25% DS.

With low power, water and polymer consumption, the WTDS Disc Press can really deliver value to your sludge disposal process.

Would you like to:

Recover 50% to 95% of your OPEX associated with sludge disposal

Reduce tanker visits by up to tenfold

Significantly reduce your treatment plant’s Carbon footprint

Typical Business Case

Sludge transport cost (£/m3): £20

Liquid sludge produced per week - 60m3 @ 5% Dry Solids -

Annual cost to transport: £62,400

Cake produced per week - 10m3 @ 25% Dry Solids -

Annual cost to transport: £10,400

Annual saving on transport costs: £52,000 -

Annual chemical costs: £4,056

Annual power costs: £2,409

TOTAL ANNUAL OPERATIONAL SAVINGS: £45,535

Case Study

Read DHMO’s case study on the recent installation of a WTDS-3-1 Disc Press Installation here.

For more information, please contact us directly.

For more information, please contact us directly.

CONTACT