Decanter Centrifuges

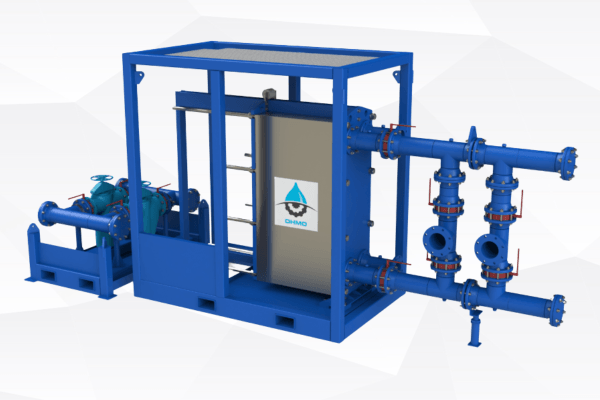

Separation and Heat Transfer Solutions

What are Decanter Centrifuges?

Decanter centrifuges are designed to remove large quantities of low gravity solids from their feed liquid. This is achieved by subjecting the fluid to extreme centrifugal forces, causing the solids to settle on the bowl’s inner wall, before they are discharged continuously by an internal auger.

Decanters come in either 2 phase or 3 phase. 2 phase decanters are designed only to separate solids from a liquid and 3 phase decanters can separate solids and two liquid phases, such as oil and water.

DHMO Decanter Centrifuges

In partnership with Alfa Laval, DHMO offers a wide range of decanter centrifuges for sale or for hire. These decanters provide exceptional performance and are suitable for various applications, with bowl diameters ranging from 9" to 30". All our Decanter Centrifuges can be built to ATEX standards and both VFD and hydraulic drive systems are available.

Decanter Specifications:

Bowl diameter: 9” to 30”

Particle diameter: 5mm to a few microns

Energy consumption: Low

Alfa Laval Decanter Centrifuges

The Alfa Laval range offer high efficiency and continuous operation. Their low capital cost/capacity ratio, low maintenance costs and low energy consumption help to keep costs down.

Depending on the industry and needs, there are different types of decanters available, which DHMO advises on. Based in Aberdeen and working across the UK and worldwide, we work in all sectors, including oil & gas, energy, industrial waste, food and beverage, manufacturing and municipal waste.

As specialists in separation and filtration, we offer consultancy support and advice, as well as ongoing maintenance and servicing. We offer 24/7 support.

For more information, please get in touch with us directly.

CONTACTOur services include:

- Centrifuge Supply & Servicing

- Chemical Cleaning

- Analysis

- Process Optimisation

Having a large hire fleet of centrifuges and other dewatering technologies helps us appreciate the absolute requirement to maintain dewatering machinery to a reliable and serviceable condition. It also gives us the ability to deal with breakdowns immediately, when they occur.

Major repairs are carried out at our Aberdeen workshop. Machines are returned to clients’ premises ready for service, following which, installation and commissioning is carried out either in-house or by DHMO’s trusted field engineers.

For more information on DHMO’s oil & gas services, please contact us directly. Disc Stack Separators

Contact us to discuss your requirements

CONTACT