How to optimise disk stack centrifuges

When a business grows, so too does its capacity and for many companies, equipment and machinery can end up working harder to cope with the additional demand. In industries like oil & gas or food & drink, disk stack centrifuges can quickly end up over-worked, which can have a detrimental impact on the process and, on the equipment itself. Optimising disk stack centrifuges is therefore a must.

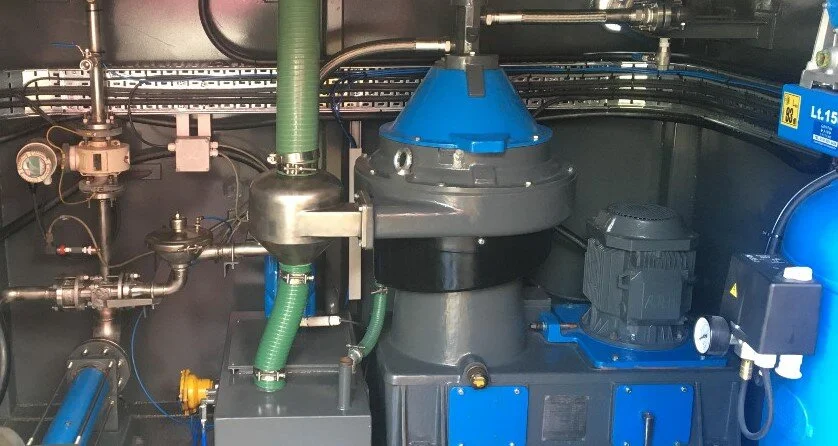

Disk stack centrifuges

Disk stack centrifuges are used to separate very fine particles and liquids of varying densities. They operate at a higher speed of rotation than decanter centrifuges and play an important role in countless industries, such as food & drink, pharmaceuticals and oil & gas. As capacity increases, fluids are forced to spend less time in the bowl, which prevents centrifugal forces from doing their job properly and separating the component phases.

Lowering the feed rate

Lowering the feed-rate will allow the centrifuge more time for processing, which will improve the output quality. However, for some businesses, there is a need for added capacity and reducing the feed-rate is, simply, not an option. Note that although it is technically possible to pump the maximum level of fluids through the machine, it is not ideal for its performance and will result in inefficiencies.

Other areas to check for optimisation

If a centrifuge is consistently run at more than 90% capacity, it is likely that a new, larger unit is needed. But, before investing, it’s worth looking at other areas that could help with optimisation and solve the problem, such as:

· Liquids

How are the liquids being handled upstream?

Could upstream processes cause emulsification, reducing separation efficiency?

Could good fluid handling practices result in reduced solids loading?

· Oxygen pick-up

Is there the potential for oxygen pick-up?

· Temperature

Is the temperature optimal at the inlet to the centrifuge?

· Flow through inlet

Is feed/ inlet pipework optimal for separation efficiency?

If there are issues with any of these areas, then these should be addressed in the first instance.

Regular centrifuge maintenance will help optimisation

Having a regular maintenance programme in place will pick up on any inefficiencies and help with optimisation. Optimising centrifuges will also keep maintenance and servicing costs down. Working with a partner, who understands the equipment and how to get the best out of it to support business growth will help. At DHMO, we recommend considering the growth plans of the company before purchase and considering all options, as there are many short-term solutions which can help the business through growth spurts.

For more information, contact DHMO on 01224 920 036 or email general@dhmo.co.uk.